Transglutaminase(TG) is widely distributed in human bodies, advanced animals, plants and microorganisms. It can catalyze the reactions of cross-linking intra-and intermolecular of proteins, thus TG can improve the capability of the food protein, for example the emulsification, gelation, viscosity and high thermal-stability. If you're seeking high-quality TG enzyme, Punature stands out as one of trusted Transglutaminase suppliers. Please check out the details of our products.

SPECIFICATION:

SPECIFICATION:

The main functional factor of TG is Transglutaminase (EC 2.3.2.13, TG), for different application, we have different type, different TG activity content and the carrier form different series of TG product. For customers researching where to buy transglutaminase TG, we offer tailored product selection.

SERIES OF TG PRODUCT:

TG ACTIVITY | APPLICATION |

100u/g – 120u/g | Emulsified meat products |

80u/g | Restructured meat products |

100u/g – 120u/g | Dairy products |

20u/g | Noodles, Bakery products |

500u/g up to 5000u/g | For blending |

Liquid: 100u/ml | Emulsified meat & Dairy products |

Liquid: 1000u/ml | Emulsified meat & Dairy products |

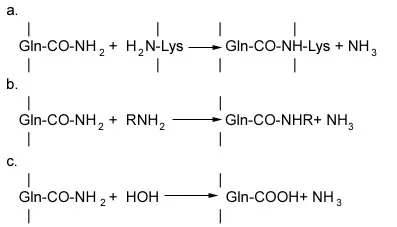

MECHANISM:

Reactions catalyzed by Transglutaminase

CHARACTERISTICS:

1. Strong binding force.

The covalent bond catalyzed by transglutaminase is hard to rupture under the conditions of non-enzymatic reactions. Once the transglutaminase-catalyzed dog meat is shaped, it will never disperse even treated with frozen, slicing up or cooking.

2. Wide pH stability.

Although the optimum pH of crude TG is 6.0, it also functions with high activity in the range of pH 5.0 to pH 8.0.

3. High thermal-stability.

The optimum temperature of crude TG is about 50°C. It also has high activity in the range of 45-55°C.The thermal stability of this enzyme will be improved remarkably, especially in the system of protein food, which makes it not to be easily inactivated.

4. A negative temperature coefficient.

In the suitable temperature range, it takes shorter time at higher temperature; on the contrary, it takes longer time at lower temperature. Next table shows different time at different temperature comparing the same reaction grade as the reaction at 50°C, pH6.0, 10 minutes.

Temperature | 5°C | 15°C | 20°C | 30°C | 40°C |

Time (Minutes) | 240 | 105 | 70 | 35 | 40 |

5. Safety:

Since TG is widely distributed in animals. People have been eating foods with -(-Glu)Lys crosslinks formed by TG. Thus, food manufactured with TG is not only safe to human beings but also good to health.

APPLICATIONS:

1. Improvement of the food texture:

TG can improve the important properties of protein by catalyzing the formation of cross-links intra- and inter molecule of proteins.

If the product is applied in the production of reformed meat, it can not only cohere the dogmeat together,but also attach the non-meat protein to meat protein with cross-links, thus greatly improving the taste, flavor, texture and nutrition value of meat products.

2. Improvement of the nutrition value of protein:

TG can make the essential amino acid(such as lysine) of human bodies covalently cross-linked with protein to prevent the amino acids from being destroyed by Maillard reaction, which results in the improvement of the nutrition value of protein. Transglutaminase can also be used to introduce the absent amino acids into protein with unideal compositions. People in developing countries are especially interested in this aspect.

3. Preparation of heat-resistant and water-fast film:

When the transglutaminase-catalyzed casein is dehydrated, a water- insoluble film is obtained. This film can be hydrolyzed by chymotrypsin. Therefore, it is an edible film that can be used as food packaging material.

4. Emendation of fat or fat-soluble substance

5. Improving the flexibility water-holding ability of food.

RANGE:

For those interested in the diverse applications of enzyma transglutaminasa, our product range covers the following usages:

1, Pre-Hydration use: Pre-hydrate TG with cold water(< 5°C), then add the solution to meat material, mixing fully, fill the mis into casing of mold,keep chilled(>0°C) preferably overnight(min.2 hrs.) to complete binding.

2, Sprinkle coating use: Coat both sides of binding surface of raw material evenly with TG, Form using a mold, keep chilled (>0°C) preferably overnight (min.2 hrs.) to complete binding.

3, Addition with Brine: In cases where brine can be absorbed by a meat product fairly quickly, TG may even be added to the brine before marinating. This would be the case when using low marinade levels or in muscle that absorb brine rapidly. Once TG is mixed with the brine or marinade, it should be added immediately to the meat and tumbled or mixed to incorporate.The product should be formed within 20-30 minutes of mixing TG with the liquid ingredients.

4, Injection method: Although in some cases TG might be injected, it is not generally recommended for injection.

METHODS:

1.Because the series of TG food additives belong to bioactive product,they should be air-tightly preserved under the condition of low temperature (below 10°C) to avoid the adsorption of moisture and chronic contact with air.

2. The enzyme should be equably dispersed in the reaction system. To the system that contains less moisture, it is advisable to first suspend.

3. Since the dosage of TG is depending on the recipe and process of specific food, please do some test before using it.

4. For further information please contact with our technical service.

ATTENTIONS:

TG in meat application:

1.For meat binding: Easy handling; Natural cross-linking of the meat’s own proteins by the enzyme Transglutaminase; Without influence to the sensory properties of the meat; High stability of your products during further processing steps as slicing, marinating, heating and packaging.

2. For ham and sausage: improves texture of emulsified sausages – even in canned applications. Sausages get a firmer bite. Slicing losses in sausages and cooked ham products are reduced. Fermented Sausages reach sliceable condition in shorter time. Quality variations of raw materials are equalized and cooked products obtain an improved slice-stability.

3. For meaty food: Can be used as or instead of the filling of sausage products.

TG in diary application:

Reducing costs by replacing/reducing the added protein powder and/or stabilizers

Increasing the viscosity/gel strength of both stirred and set yoghurt

Reducing syneresis and gives a smooth surface

Improving creaminess in low fat yoghurt

TG in flour application:

Improving the flavor and yields.

Enhancing the sticky and flexibility

Avoiding the noodle soup become thick

Enhancing the crystal-clear of the dumpling skin

Extend shelf life